Mfg for Dummiess

Wiki Article

The Main Principles Of Oem

Table of ContentsThe 30-Second Trick For Additive ManufacturingThe Lean Manufacturing IdeasThe Mfg PDFsAn Unbiased View of Lean ProductionAll About Lean ProductionLean Manufacturing Fundamentals Explained

The text on this page is an example from our complete White Paper 'Shot Moulding for Customers' - * Example text * - for full overview click the download button above! Intro This guide is meant for individuals that are aiming to resource plastic mouldings. It offers a much required insight into all that is included with creating plastic components, from the mould device called for to the moulding procedure itself.If you intend to check out additionally, the overview covers sorts of mould tools, as well as unique ending up processes such as colours & plating. Words that are underscored can be located in the reference in the appendix ... Component I: Moulding: The Basics The Advantages of Shot Moulding Plastic shot moulding is an extremely exact procedure that supplies a number of advantages over various other plastic handling methods.

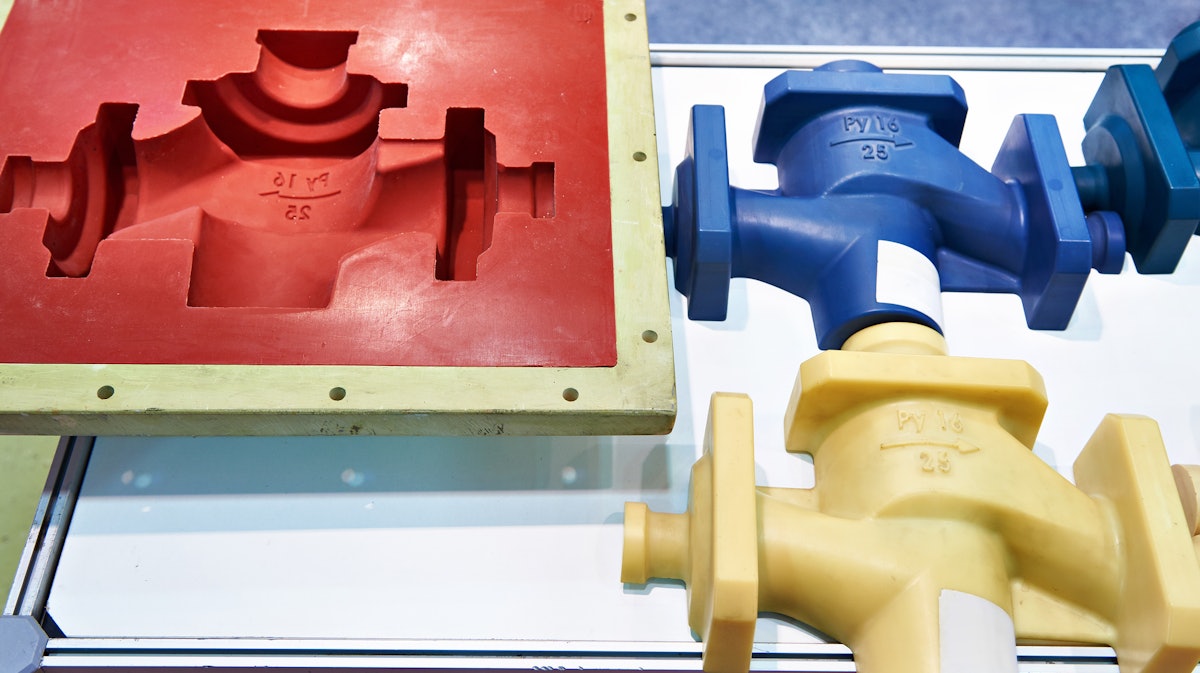

Precision is excellent for very intricate parts. Compared to various other methods, moulding enables you to integrate even more functions at really tiny resistances. Look at the image to the right. lean manufacturing. You can hold this moulding in the palm of your hand as well as it has managers, ribs, metal inserts, side cores and openings, made with a sliding shut down attribute in the mould tool.

The Facts About Die Casting Revealed

from material feed Product melting; material injectionProduct cooling time and ejection to the re-closing of the mould tool ready for all set next cycle. Draft angles - The walls of a moulded component ought to be somewhat tapered in the direction in which the component is ejected from the mould device, to enable the part to be ejected conveniently.

Ejector stroke - The pushing out of Check Out Your URL ejector pins to eject the moulded part from the mould device. Ejector stroke speed, size as well as timing requires to be carefully managed to prevent damage to the ejectors and mould device, but at the same time make the moulding cycle as brief as possible.

Some Known Details About Additive Manufacturing

Ribs - When a plastic mes system component has slim walls, ribs are included in the layout to make the slim wall surfaces more powerful Side cores - Side activity which produces a feature on a moulded part, at an opposing angle to the typical opening instructions of the mould tool. manufacturing. The side core needs to be able to retract as the plastic part can not be ejected otherwise.

Wall surfaces - The sides of a moulded component The message on this web page is a sample from our complete White Paper 'Injection Moulding for Buyers'.

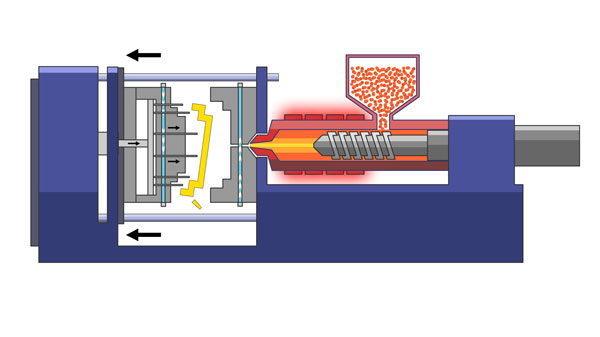

Manufacturing process for creating parts by infusing molten material right into a mould, or mold and mildew Simplified diagram of the process Shot moulding (U.S. punctuation: injection molding) is a production procedure for generating parts by infusing molten material into a mould, or mold. Injection moulding can be done with a host of materials primarily consisting of metals (for which the procedure is called die-casting), glasses, elastomers, confections, and the majority of typically polycarbonate and also thermosetting polymers. Injection moulding is commonly utilized for making a variety of parts, from the smallest elements to entire body panels of vehicles. Injection moulding utilizes a special-purpose machine that has three parts: the shot device, the mould and also the clamp.

The Single Strategy To Use For Hon Hai Precision

, with the volume used of the former being considerably higher.: 13 Thermoplastics are common due to features that make them highly appropriate for injection moulding, such as ease of recycling, flexibility for a wide range of applications,: 89 and ability to soften and also flow on home heating.In several tooth cavity moulds, each tooth cavity can be similar and develop the exact same components or can be one-of-a-kind and create multiple different geometries throughout a solitary cycle. Moulds are normally made from tool steels, however stainless-steels and also aluminium moulds appropriate for particular applications. Aluminium moulds are typically improper for high quantity manufacturing or parts with slim dimensional tolerances, as they have inferior mechanical buildings and also are a lot more vulnerable to wear, damage, and deformation throughout the injection as well as clamping cycles; however, aluminium moulds are cost-efficient in low-volume applications, as mould manufacture costs as click this link well as time are considerably decreased.

When sufficient product has actually gathered, the product is forced at high stress and velocity right into the part developing tooth cavity. The precise amount of shrinking is a feature of the material being made use of, and can be reasonably foreseeable. To avoid spikes in pressure, the procedure generally uses a transfer position matching to a 9598% full dental caries where the screw changes from a consistent velocity to a constant pressure control.

The Of Oem

As soon as the screw gets to the transfer setting the packaging stress is applied, which finishes mould dental filling and also makes up for thermal shrinkage, which is fairly high for thermoplastics about several various other materials. The packing stress is applied till eviction (dental caries entryway) solidifies. Due to its small size, eviction is generally the very first place to solidify through its entire thickness.: 16 Once eviction solidifies, no even more product can get in the cavity; accordingly, the screw reciprocates and obtains product for the next cycle while the material within the mould cools down so that it can be ejected as well as be dimensionally stable.Report this wiki page